Measurement & Testing Methods

Standardized Quality Methods and Custom Testing Procedures

In the dynamic and demanding world of cable assembly, top quality and reliability are essential. The diverse characteristics of your cable products require customized testing procedures tailored to their specific functions.

At Schneider Kabelsatzbau, we combine proven, standardized quality tools with specially designed test adapters. This approach ensures precise and reliable results, guaranteeing that your products meet the highest quality standards.

Our expertise and commitment to quality make us your ideal partner in cable assembly. Trust Schneider Kabelsatzbau to enhance efficiency, reduce costs, and maximize customer satisfaction.

Contact us today to learn more about our services and how we can help you achieve your quality goals. We look forward to working with you!

Quality Tools & Methods

- Initial Sample Inspection Reports (VDA, PPAP)

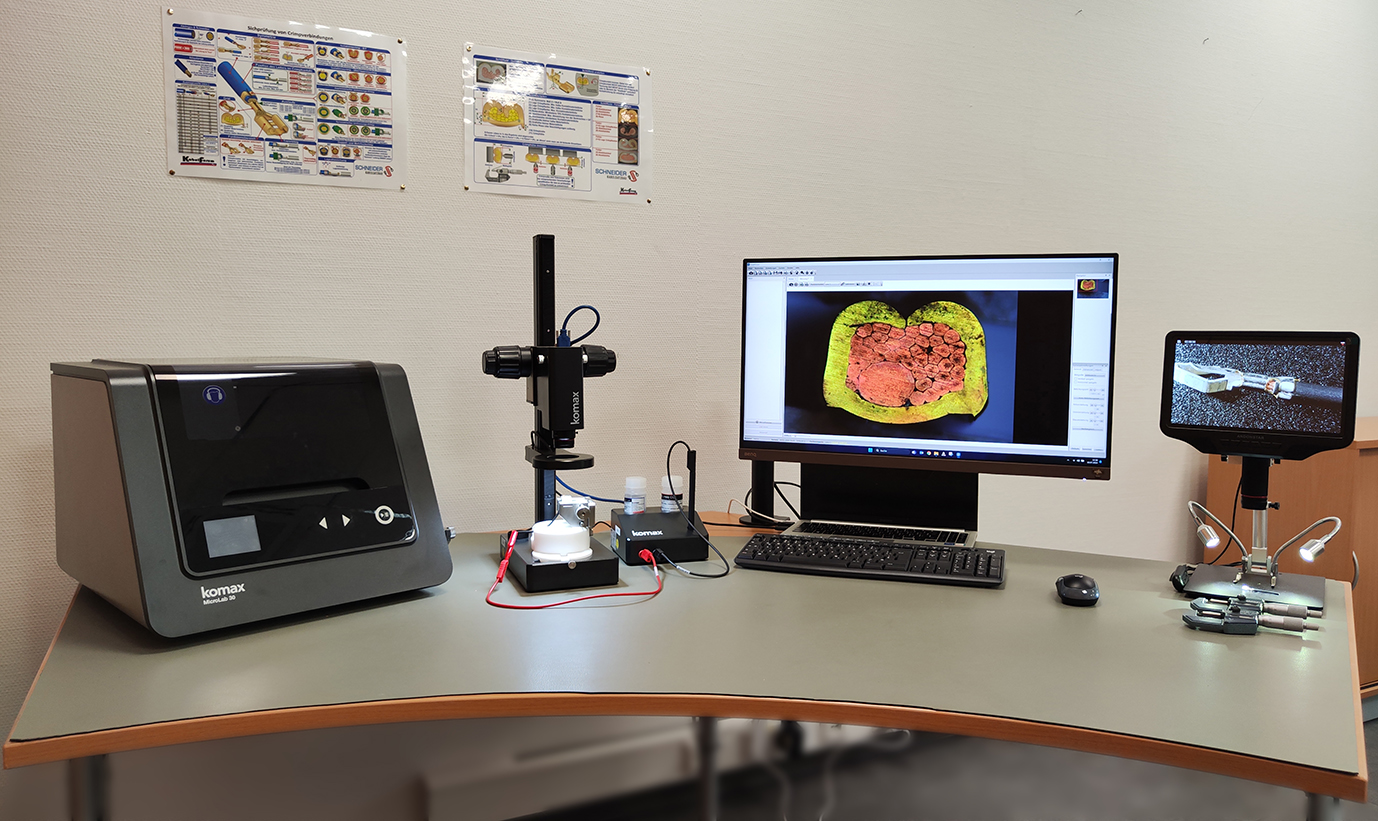

- Crimp Analysis using custom cross-sections

- Poka Yoke error-proofing

- Component Testing with vision sensor camera systems

- 100% or Sample Inspections based on customer requirements

- Creation of Test- / Assembly Boards

- Automated Monitoring of crimp force and height

- 6S Method for workplace organization

- Crimp Evaluation using microscopes

- Motorized Pull Tests for crimp and weld connections

- Transparent Documentation of all quality data

- Creation of Electrical Test Adapters

Electrical testing:

- Continuity test / occupancy test

- Short circuit test

- Insulation test

- Diode test

- Resistance measurement

High voltage test