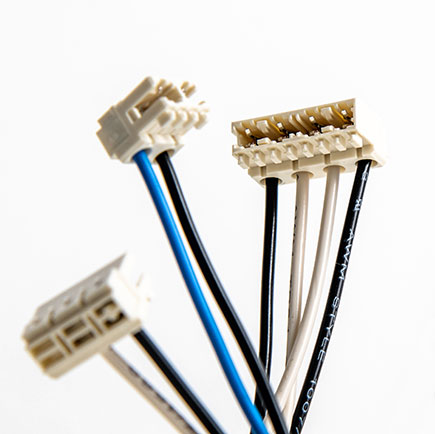

Compacting

Welded compactly

In addition to crimping, Schneider Cable Harness Assembly offers another high-quality joining process for your cable assembly with compacting. In compacting, the conductor ends are pressed and fused into extremely precise square or rectangular cross-sections using resistance welding. Besides achieving an exact shape, welding ensures excellent durability and prevents fraying of the ends. Cables processed through compacting are well-suited for automated further processing and guarantee high mating cycles even without ferrules. We use resistance welding equipment from Strunk, allowing us to handle serial production efficiently.